How about products and service of Xintao Technology?

2020-03-23

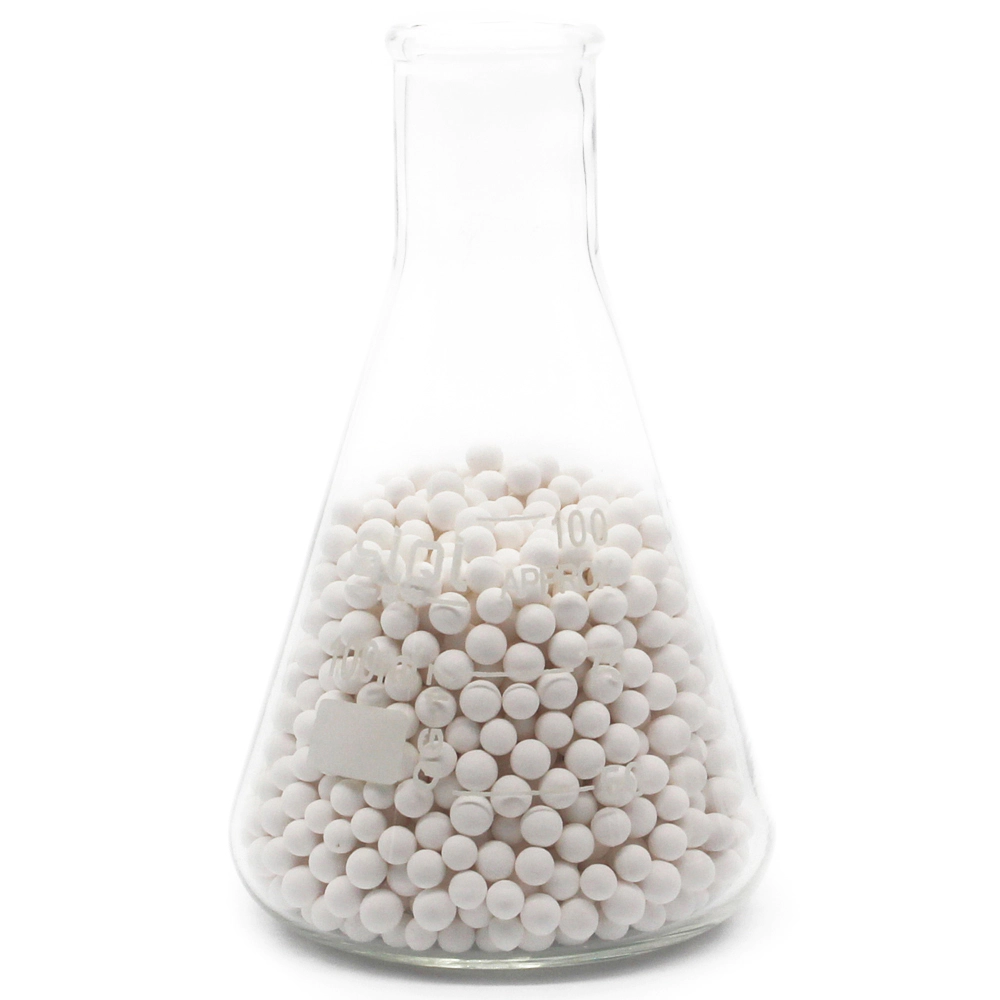

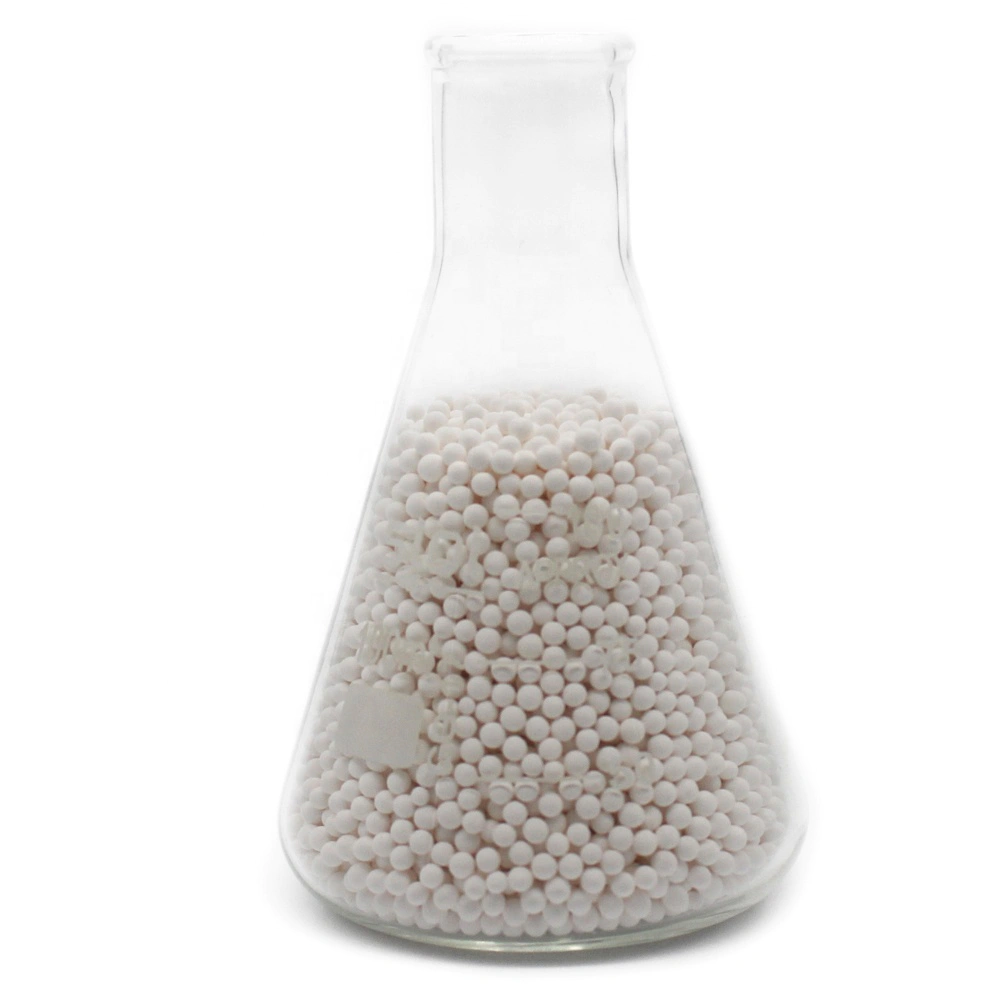

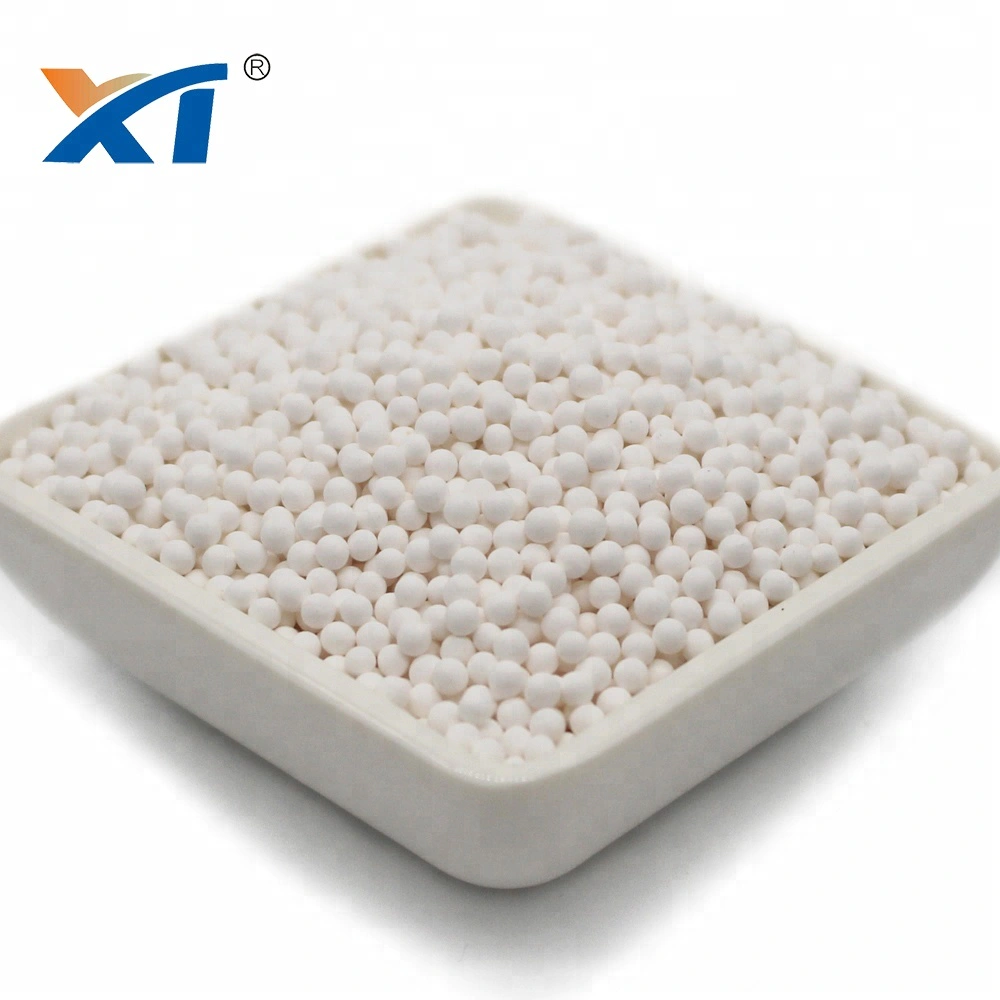

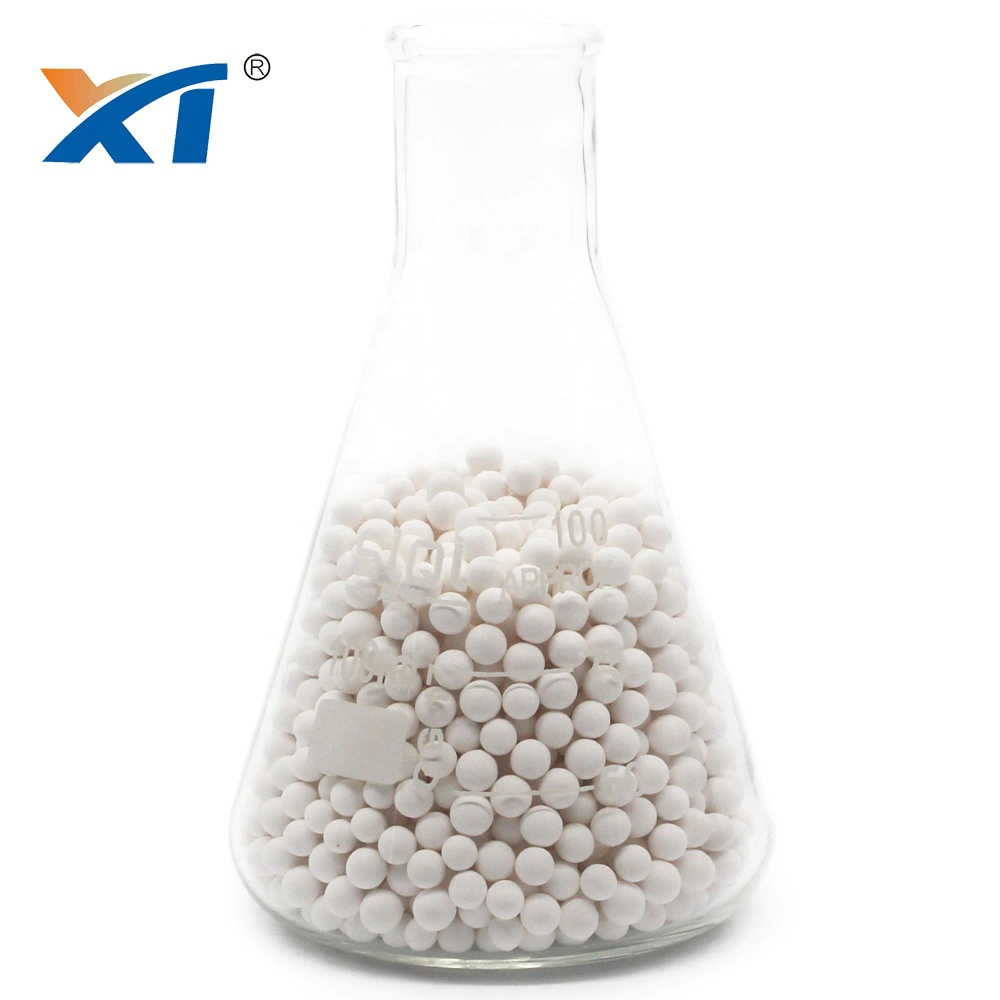

As a company focusing on the manufacturing of activated alumina beads and also customers' needs, Jiangxi Xintao Technology Co., Ltd. has received high appraises from our existing customers mainly in the aspects of high-quality products and service. Under the guidance of business principle - Quality First, we strictly supervise every production step including design and manufacturing. A high qualification ratio is what we promise to offer. In terms of the service, we have a service team consisting of elites. Their years of devotion in the industry gives them enough confidence to provide customers with the most reliable and efficient service throughout the whole cooperation process.

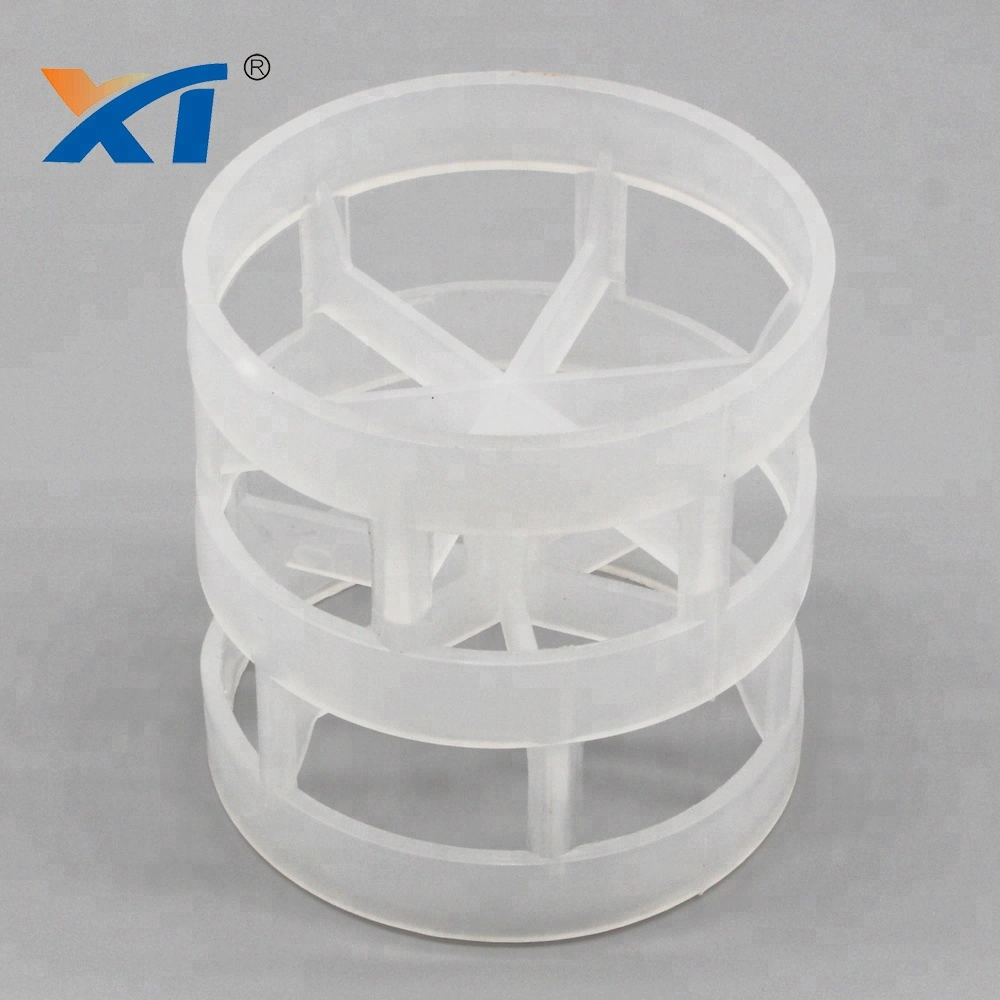

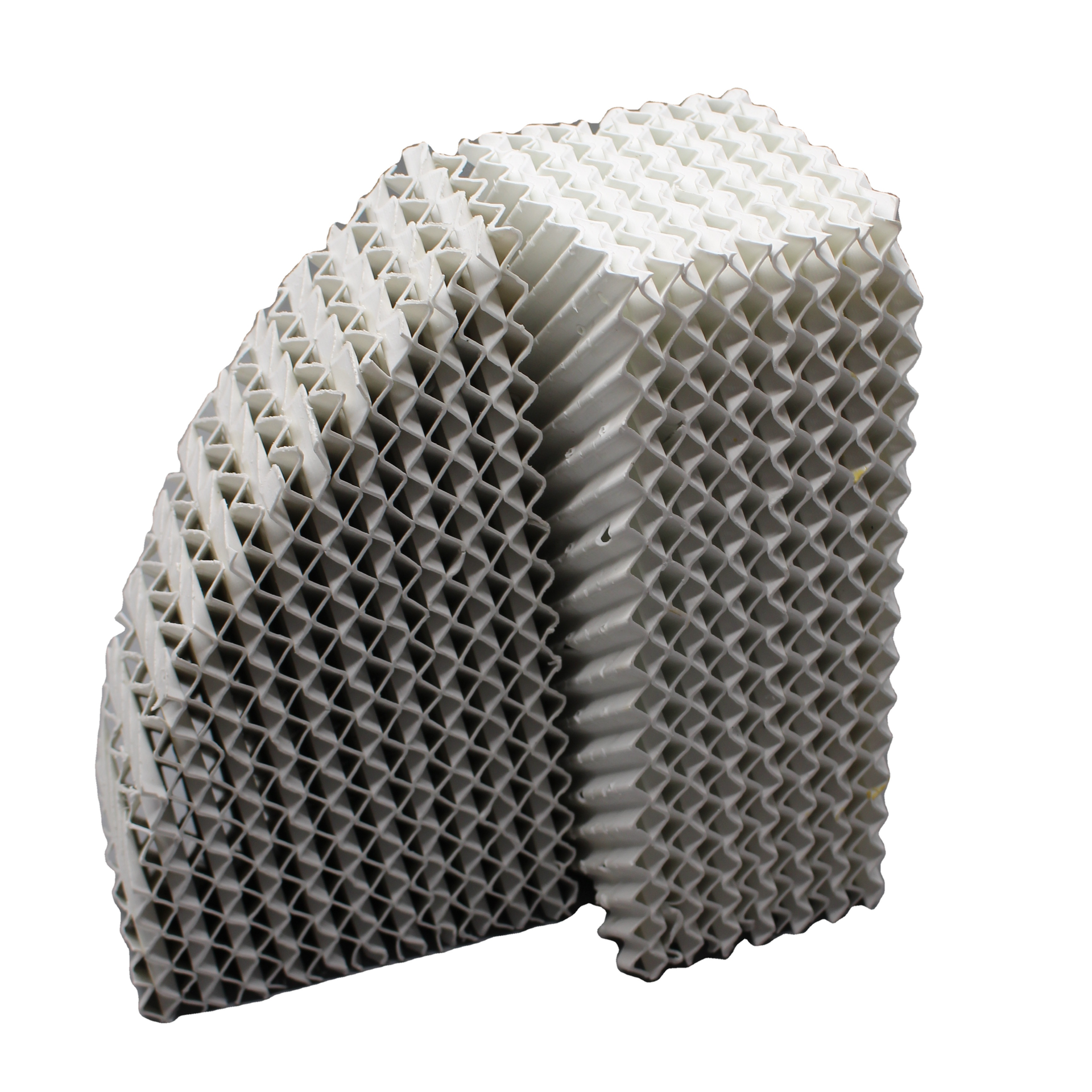

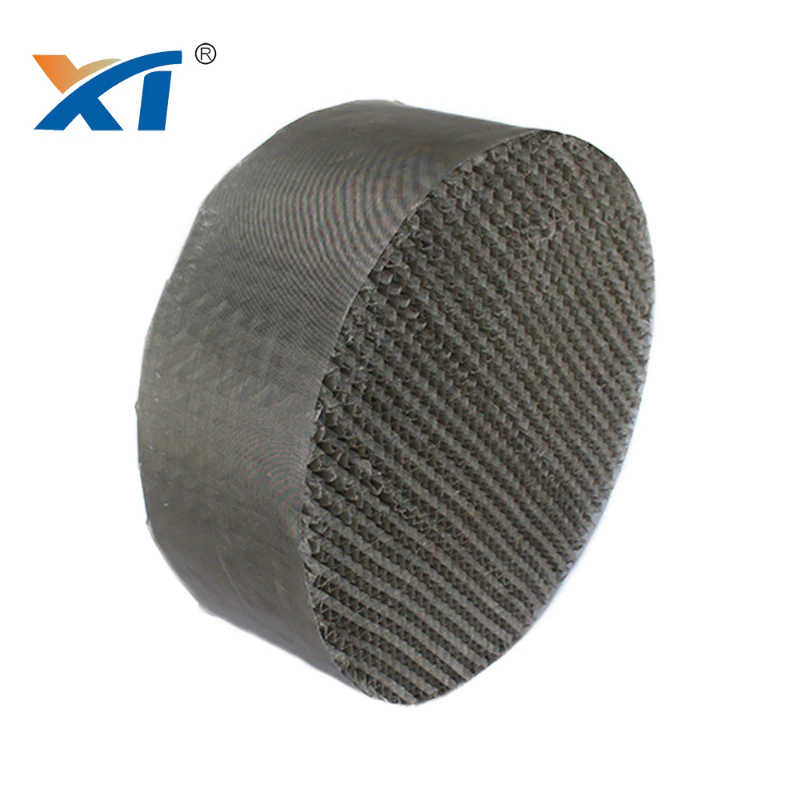

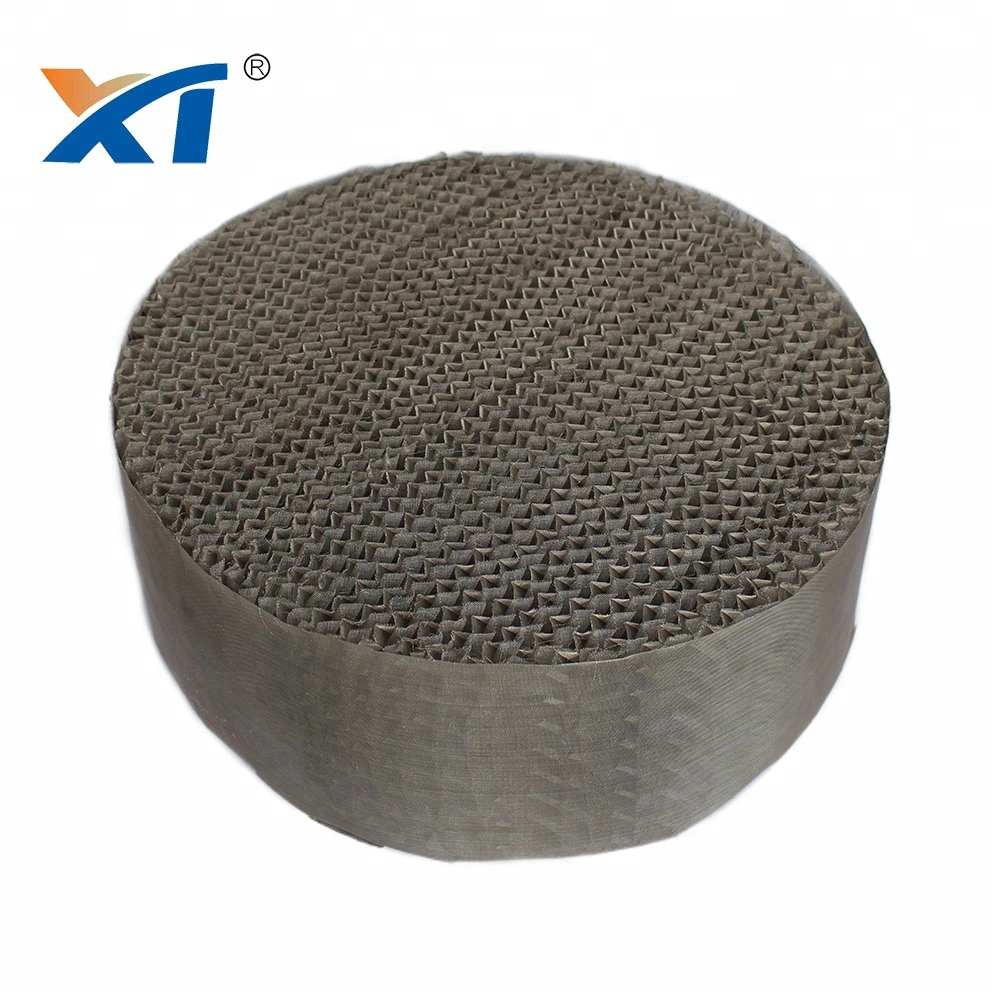

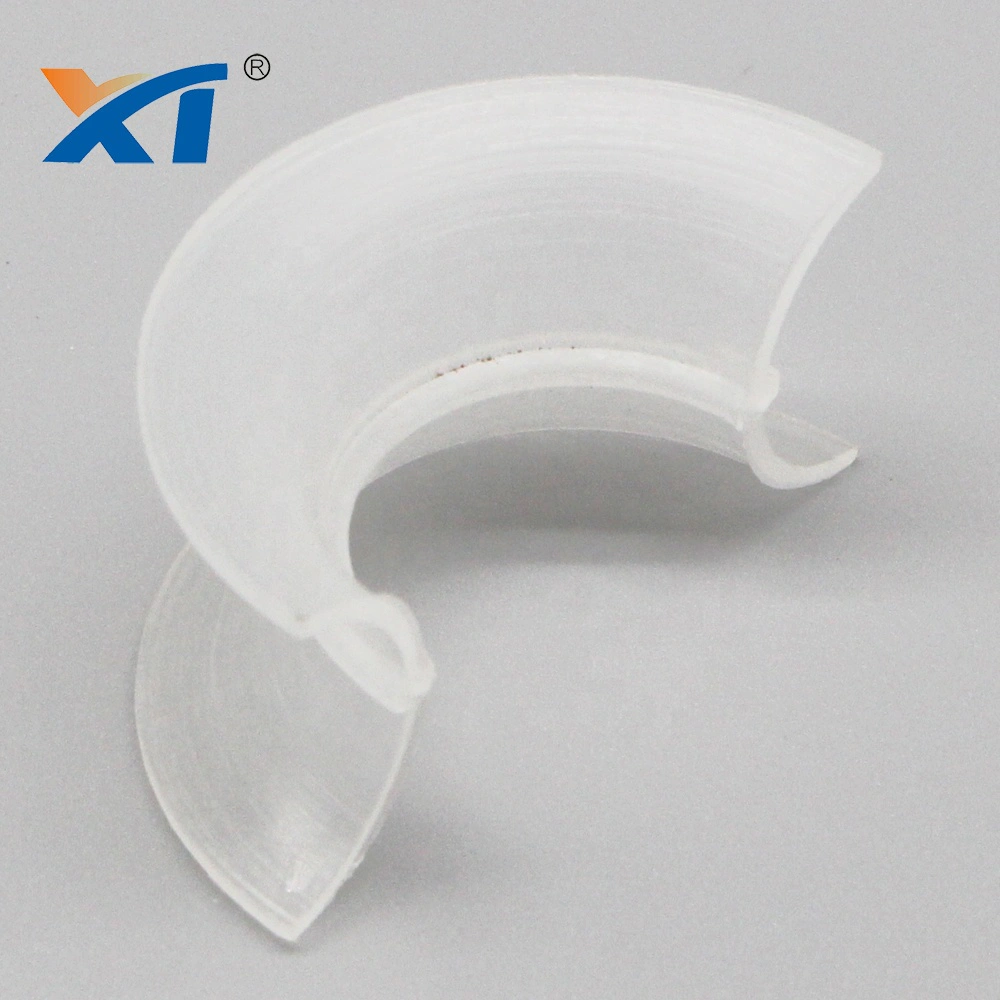

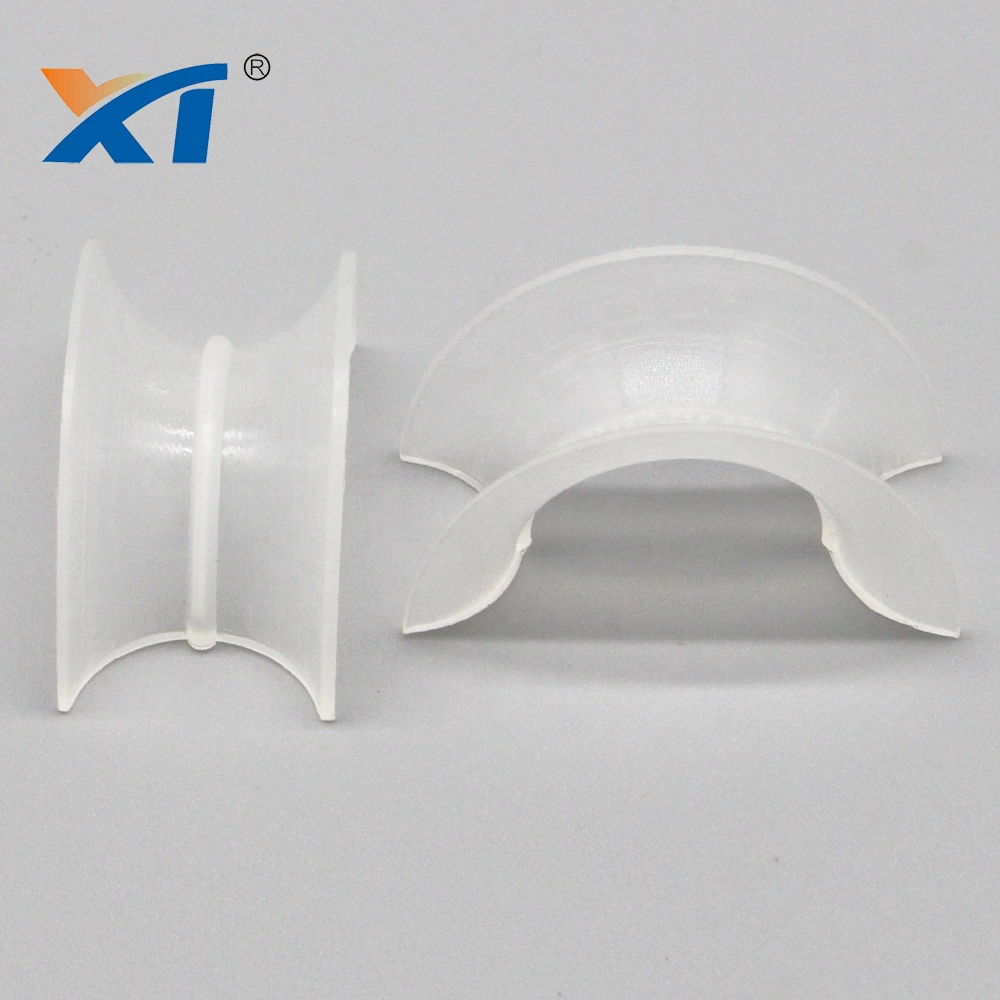

Xintao Technology is a specialist manufacturer and producer of intalox saddle packing. Since the establishment, we hold a safe lead in this industry relying on competence. The activated alumina series is available in a wide range of types and specifications. There are four sections of Xintao Technology silica alumina catalyst quality controlling process. The four sections are cutting, sewing, washing, and finishing, which must be checked based on some criteria. It has been broadly used in many industries such as electric power, petroleum, chemical, metallurgy, environmental protection, pharmaceutical, aerospace, and fire protection. Since the amount of heat produced by traditional lighting is so high, the risk of fire due to overheating is obvious. Luckily, this product does not come with the same risks, since it always remains cool for use. This product has a high level of purity.

We adopt technologies and practices which reduce negative impacts on the environment, ensuring a commitment to environmental protection during all stages of project development.

Xintao Technology is a specialist manufacturer and producer of intalox saddle packing. Since the establishment, we hold a safe lead in this industry relying on competence. The activated alumina series is available in a wide range of types and specifications. There are four sections of Xintao Technology silica alumina catalyst quality controlling process. The four sections are cutting, sewing, washing, and finishing, which must be checked based on some criteria. It has been broadly used in many industries such as electric power, petroleum, chemical, metallurgy, environmental protection, pharmaceutical, aerospace, and fire protection. Since the amount of heat produced by traditional lighting is so high, the risk of fire due to overheating is obvious. Luckily, this product does not come with the same risks, since it always remains cool for use. This product has a high level of purity.

We adopt technologies and practices which reduce negative impacts on the environment, ensuring a commitment to environmental protection during all stages of project development.

پیام سفارشی

محصولات مرتبط